Case Study

Tyre Inflator

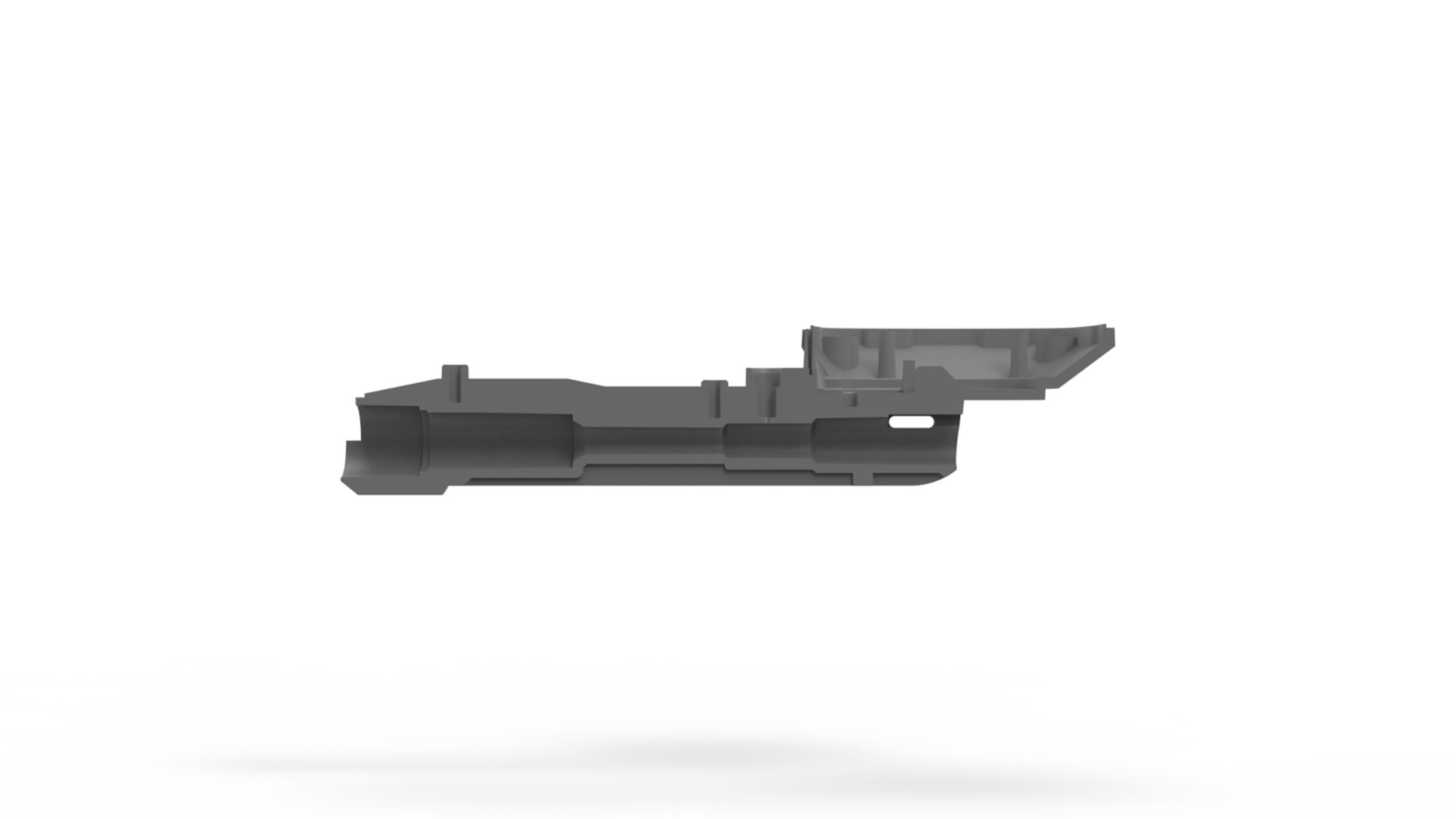

PCL Air Technology approached Laser Scanning with one of their existing tyre inflator housing and supporting technical drawings for the part. The aim was to 3D laser scan, reverse engineer and produce a native Solidworks file of the part so that PCL could further edit and remanufacture the part.

PCL chose to laser scan the existing part even though they had technical drawings as the part was reasonably old, and they wanted to confirm that the part was still within the spec of the dated technical drawings. You will see from this following case study that the drawings became an vital part of the reverse engineering process for the internal cavities where our laser scanners could not reach.

Laser Scanning.

We scanned the part in multiple setups with our handheld Nikon metrology H120 laser scanner, which is the most accurate handheld scanner available. Unfortunately, it was impossible to scan the internal cavity that ran through the part due to line of sight and access.

Reverse Engineering.

We then reverse engineered the part back to its original design intent using our specialised CAD package Geomagic Design X. Watch the short time lapsed video below to see how we achieved this.

Technical Drawings.

At the start of any project, we always ask the customer to provide as much information as possible about the part. This communication ensures that we don’t overlook any vital requirements for the part(s).

For this tyre inflator part, the internal cavity needed to be highly accurate. Unfortunately, it was impossible to capture this data with our laser scanners due to line of sight and access. Typically, if we can't capture an area due to line of sight, we can take a silicon mould of the area, remove it, scan it, and then add it to the existing data. However, to ensure accuracy, PCL decided to provide technical drawings along with the part to ensure accuracy.

Solidworks Live Transfer.

PCL finally required the part as a native Solidworks file to make additional changes to the overall design.

We reverse engineer using a CAD package called Geomagic Design X by 3D Systems. Design X is specialised software specifically for a reverse engineering application as it allows the scan data to sit in the background and be constantly referenced to ensure accuracy. Design X also has a fantastic feature called ‘live transfer’, allowing you to transfer your full design tree to various CAD packages. This live transfer is a semi-automated feature that opens both Design X and Solidworks and slowly steps through each feature of your design tree. Unfortunately, much of this process does need to be managed as some features aren't recognised and need to be manually built.