3D printing.

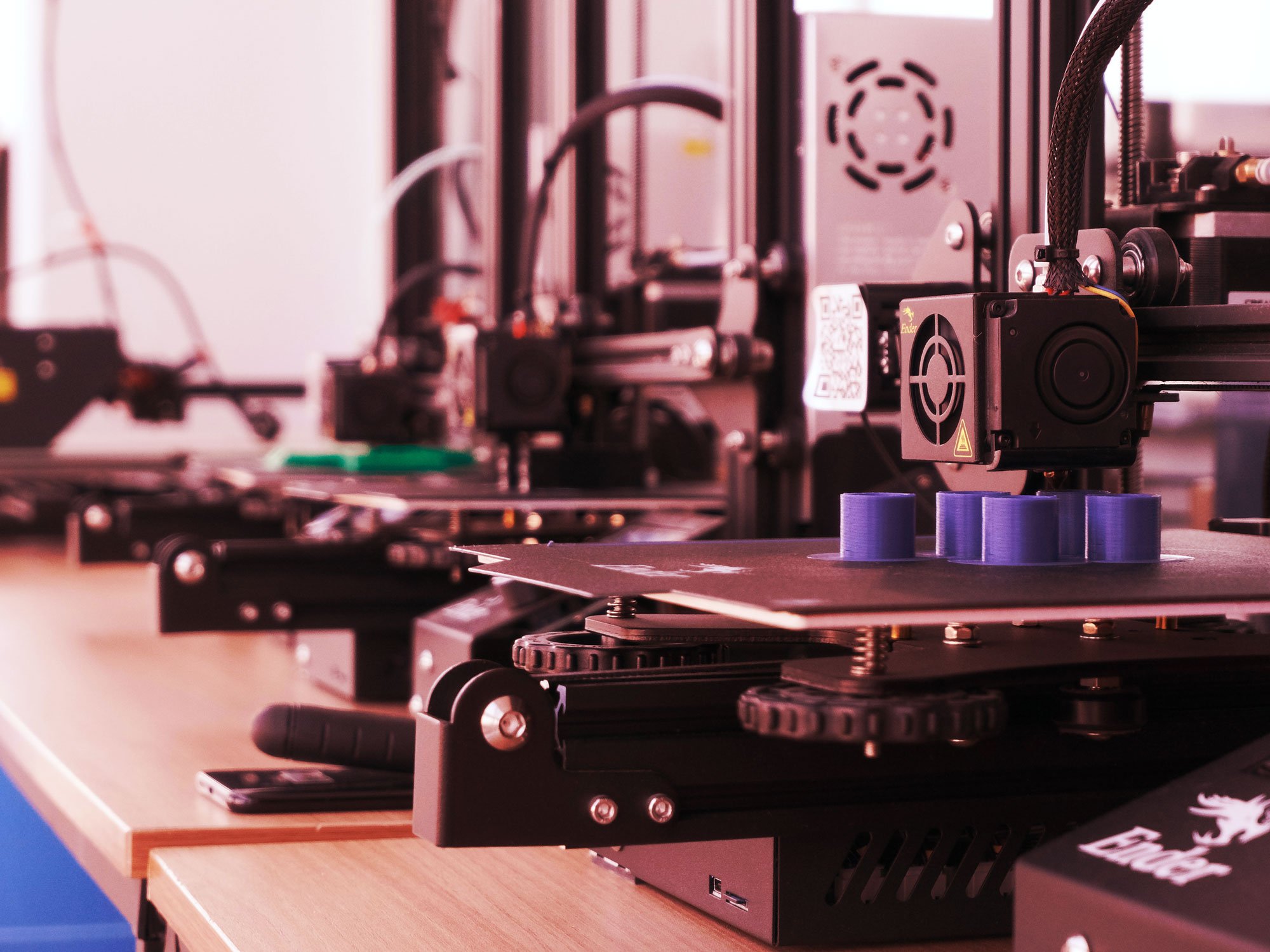

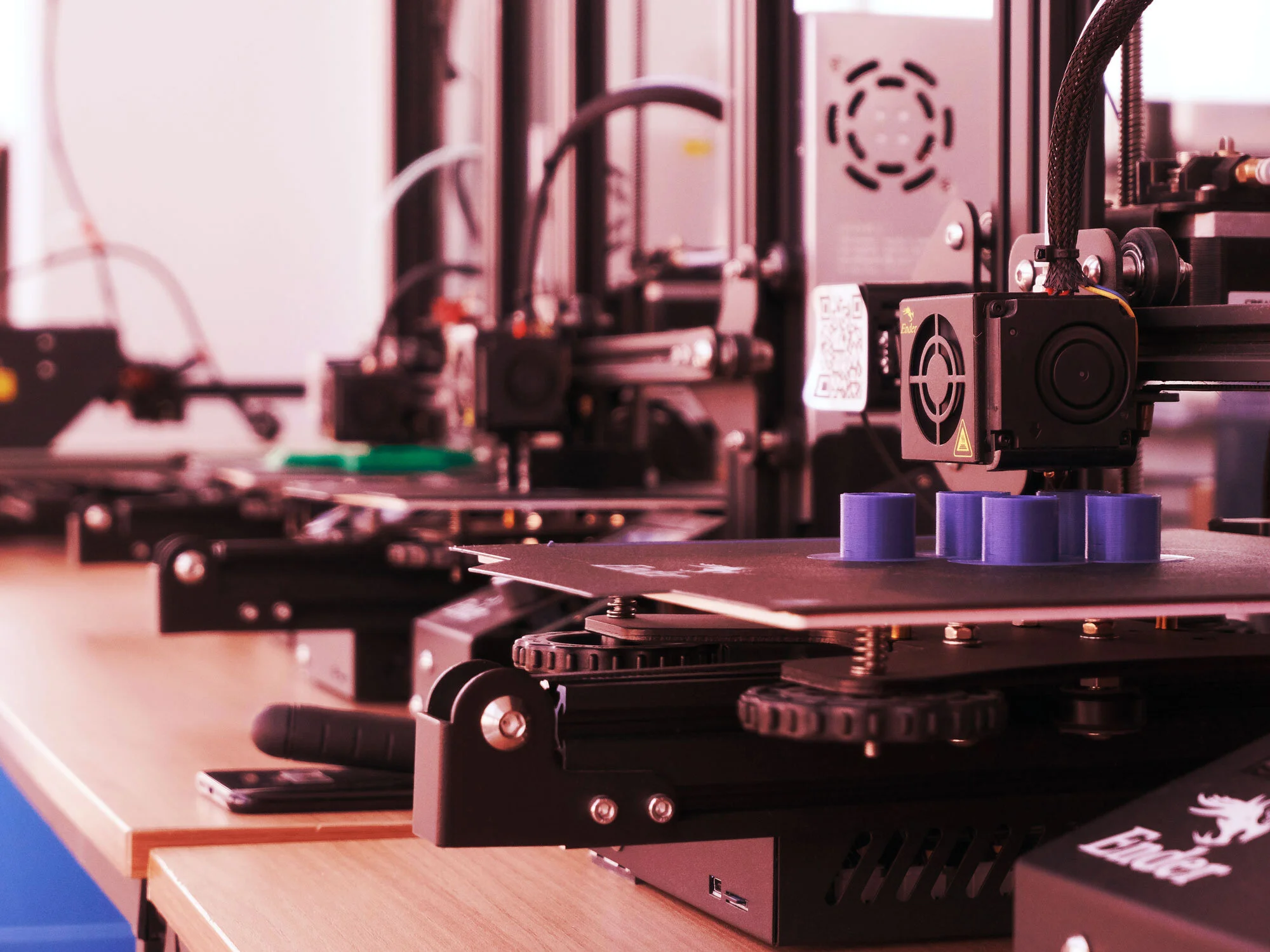

Our in-house 3D printing services can be used to prototype existing designs or 3D print directly from scan data.

3D Printing.

We offer a range of in-house 3D printing services from FDM rapid prototypes to high fidelity SLA prints.

Laser Cutting.

Our in-house dual head CO2 laser cutter is capable of cutting plastic, wood, leather and even steel (max 2mm) to an accuracy of 0.1mm.

Finishing.

Depending on your chosen method of prototyping the level of finishing required can be fairly labour intensive, but we a range of finishing options to support your project.

3D Printing.

We support a wide range of 3D printing methods and materials.

-

Fused filament fabrication, also known as fused deposition modelling, or called filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work.

-

Stereolithography belongs to a family of additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source—a laser or projector—to cure liquid resin into hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank.

-

Selective laser sintering (SLS) is an additive manufacturing technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

-

Multi Jet Fusion (MJF) is a technology that HP has specifically developed. MJF and SLS are very similar printing methods as they both belong to the powder bed fusion family. However, MJF typically provides strong, more flexible parts which are more comparable to injection moulded properties. In contrast, SLS offers a broader range of materials and colour finishes.

Laser Cutting.

Our in-house laser cutter can be used for quick prototypes through to batch production.

-

Our metal laser cutter has an oxygen assisted 150W tube capable of cutting mild steel, galvanised steel and stainless steel (up to 2mm). With a bed size of 1300mm by 900mm, we can accommodate most prototyping and small batch production work.

-

Our none-metal laser cutter has an air-assisted 80W tube capable of cutting fabrics, rubber, marble, granite, tiles, paper, leather, embroidery, acrylic, glass, plastic, MDF, hard wood etc. With a bed size of 1300mm by 900mm, we can accommodate most prototyping and small batch production work.

Learn about our services

-

What should we know about the services you provide? Better descriptions result in more sales.

-

What should we know about the services you provide? Better descriptions result in more sales.

-

What should we know about the services you provide? Better descriptions result in more sales.

Our 3D printing services are ideal for:

Turning your CAD scans into a rapid prototype

Low volume manufacture

Vacuum casting

Concept modelling

Simulation modelling

Recreating models from damaged originals

FDM

Fused deposition modelling.

FDM Printing.

Fused filament fabrication, also known as fused deposition modelling, or called filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work.

SLA

Stereolithography Apparatus.

SLA Printing.

Stereolithography belongs to a family of additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source—a laser or projector—to cure liquid resin into hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank.

SLS

Selective Laser Sintering.

SLS Printing.

Selective laser sintering (SLS) is an additive manufacturing technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

MJF

Multi Jet Fusion.

MJF Printing.

Multi Jet Fusion (MJF) is a technology that HP has specifically developed. MJF and SLS are very similar printing methods as they both belong to the powder bed fusion family. However, MJF typically provides strong, more flexible parts which are more comparable to injection moulded properties. In contrast, SLS offers a broader range of materials and colour finishes.

Let’s Discuss Your 3D Printing Project.

+44 (0) 114 257 3650

+44 (0) 7445 769 433

Unit 18, Chambers Way

Sheffield, S35 2PH