LC15Dx - Closing the gap with tactile probe accuracy.

The LC15Dx captures the smallest of details with highest accuracy providing valuable insights for components ranging from small airfoil blades to intricate sheet metal parts.

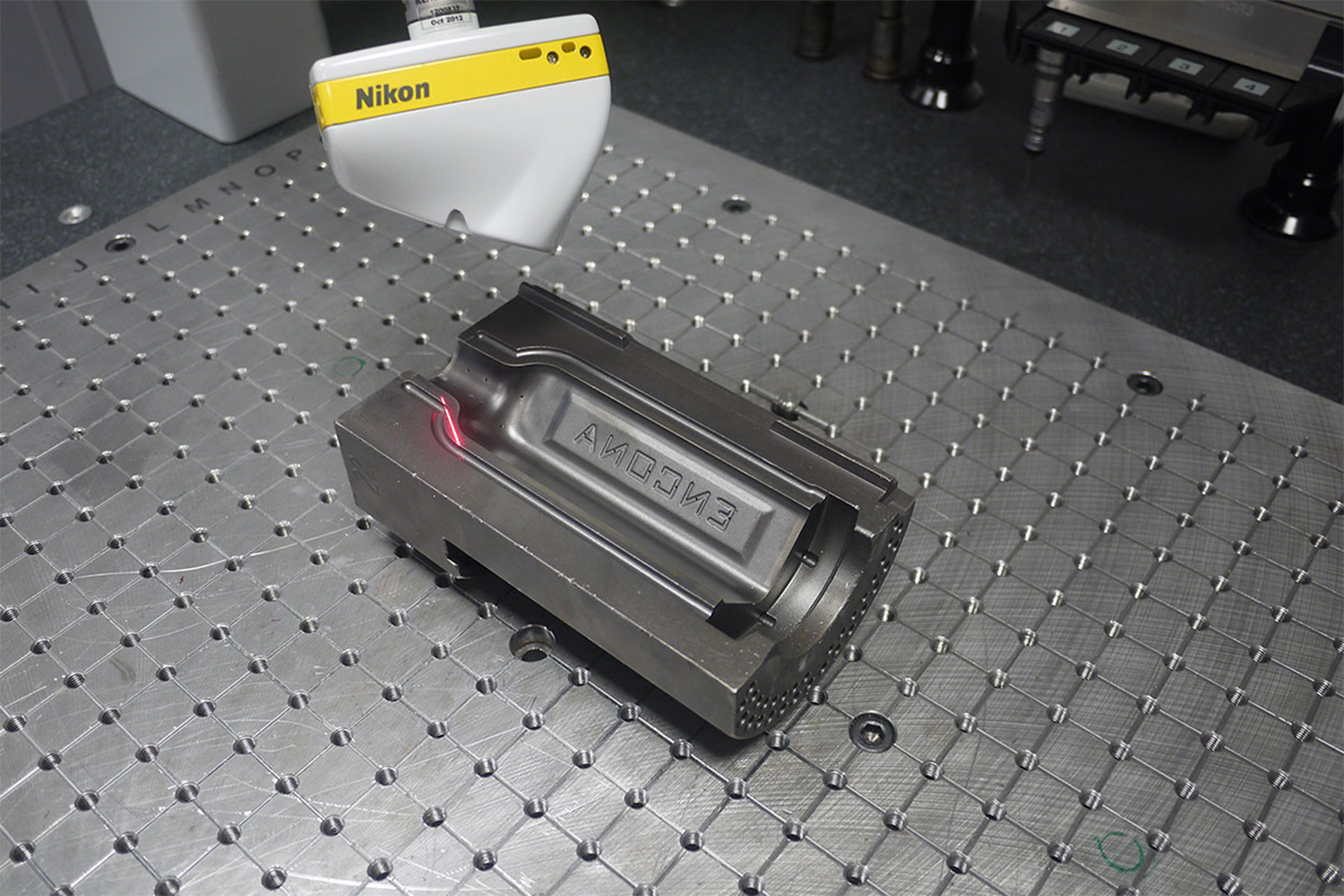

The LC15Dx CMM laser scanner provides non-contact measurements at the highest accuracy level.

In terms of the precision with which data is acquired, the performance of the LC15Dx CMM laser scanner is close to that of a tactile probe. The scanner enables measurement at the highest accuracy level, offering fast and detailed insight for quality control of components ranging from small, complex aerofoil blades to intricate sheet metal fabrications. Even flexible and fragile parts may be inspected accurately and without damage.

Due to custom-designed, top quality Nikon optics, the cost-effective scanner captures the smallest detail with high precision while maintaining speed and data quality. It does this by optimising the laser settings in real-time to match the type and reflectivity of the material, without the need for surface preparation.

Key Benefits.

Viable alternative to a tactile probe for an increasing number of high precision CMM applications.

Measure a wider variety of parts, geometry and materials more efficiently, including small details and fragile parts.

A complete 3D visualisation of dimensional quality using Colour Mapping, with the detail necessary for further analysis.

Applications.

3D digitizing with the highest detail

High precision parts and small geometry (composites, blades, impellers, medical devices, etc) with complex surfaces

Features (Slot, holes, studs, etc)

Closing the gap with tactile probe accuracy.

An LC15Dx is a viable alternative to a tactile probe for high precision CMM applications. The smallest part details can be captured with best-in-class accuracy. Thanks to solid state laser scanner technology and an innovative calibration method, the LC15Dx is closing the gap between laser scanning and tactile probing, achieving accuracies to within microns. Unlike a tactile probe, however, the scanner uses non-contact 3D laser triangulation to measure the surface directly and eliminate probe compensation errors. Full thermal compensation means the maximum accuracy is achieved as soon as the scanner is powered on.

Scan glossy or multi-material surfaces.

Nikon's patented Enhanced Sensor Performance (ESP3) maintains accuracy, speed and data quality by intelligently adapting the laser settings for each measured point in real-time. A wider range and mixture of surface materials, finishes, colors and transitions can be measured more efficiently without user interaction, manual tuning or part spraying. Unwanted reflections from shiny surfaces are neutralized by an advanced software filter, while changes in ambient light are absorbed by a high grade, daylight filter. For the most extreme parts and materials, manual laser settings are also available should they be necessary.

Multi-sensor CMM.

In some cases, single-sensor technology is insufficient for measuring all the features of a component. The LC15Dx can be combined with a tactile probe to create a versatile, multi-sensor CMM. Depending on the application, both technologies can be used independently or together in the same inspection program. Fully automatic sensor changing is possible with the addition of an optional change and storage rack, which is mounted on the table of the CMM.

Widely applicable.

The capabilities of almost any traditional CMM can be expanded to include the ability to capture the complete geometry of a wide variety of parts in a non-contact and automated way. Retrofitting a CMM with an LC15Dx is a cost-effective exercise. The unit integrates with the existing CMM controller and compatible probe system to provide a versatile, multi-sensor CMM offering both non-contact and touch probe inspection.

Measurement at the speed of light.

Measuring all features of an entire part without compromising on throughput is not a problem when you can measure 70,000 points every second. As the LC15Dx passes over the workpiece, a laser line is projected onto its surface, each line containing hundreds of measurement points spaced 0.022mm (0.0008") apart. Triangulation between the laser, workpiece and sensor is used to determine the position of the workpiece in 3D space, building a full digital copy of the part to enable 3D visualization of dimensional quality using colour maps.

| LC15Dx | |

| Ball bar length (MPEE)2 | 4µm +L/350mm (0.00016 +L/13.78“) |

| Multi-stylus test (MPEAL)3 | 3.9 µm (0.00015“) |

| ISO Probing form error4 | 7 µm (0.00027“) |

| ISO Probing size error all5 | 15 µm (0.000591”) |

| ISO Probing dispersion value6 | 7,6 µm (0.000299“) |

| ISO Cone angle7 | 100° |

| Scanning speed (approx.) | 70,000 points/sec |

| Resolution (point spacing) | 22 µm (0.00087“) |

| Points per line(approx.) | 900 |

| Measuring temperature range | 18-22°C (64.4-71.6° F) |

| Operating temperature range | 10-40°C (50-104° F) |

| Weight | 370 g (0.82 lbs) |

| Ingress Protection | IP30 |

| Laser safety | Class 2 |

| Enhanced Scanner Performance | ESP3 |

| Daylight filter | Yes |

| Probe head compatibility | PH10M, PH10MQ, CW43, PHS |

All accuracy specifications valid for a CMM with an accuracy of 2µm + L/350 or better using manufacturer supplied test sphere

1Nikon Metrology test comparable to EN/ISO 10360-2 MPEP using 1 sigma sphere fit.

2Nikon Metrology test comparable to EN/ISO 10360-2 MPEE

3Nikon Metrology test comparable to EN/ISO 10360-5 MPEAL

Accuracy specifications according ISO 10360-8:2013:

4PForm.Sph.1x25:Tr:ODS,MPE : Maximum probing form error using 25 representative points in translatory scanning mode

5PSize.Sph.All:Tr:ODS,MPE : Maximum probing size error All using all measured points in translatory scanning mode

6PForm.Sph.D95%:Tr:ODS,MPL : Maximum probing dispersion value using 95% of the measured points in translatory scanning mode

7Cone angle : Region of sphere on which the measured points are selected