X-ray CT.

With Laser Scanning being Nikon Metrology official UK this provides us access to there state of the art x-ray & CT inspection services.

World leading CT technology.

In a production environment where a fast solution to a problem is essential, internal material defects, complicated assemblies and hidden geometries can all be too complex and time consuming for manufacturers’ in-house inspection capabilities. In research and development, traditional methods of cutting and slicing parts to analyse internal structure add time and expense to the prototyping process, due to their destructive nature.

If you are a manufacturer of components or assemblies incorporating plastics, metals, ceramics, electronic components or any combination of these, our X-ray CT scanning service may be able to help.

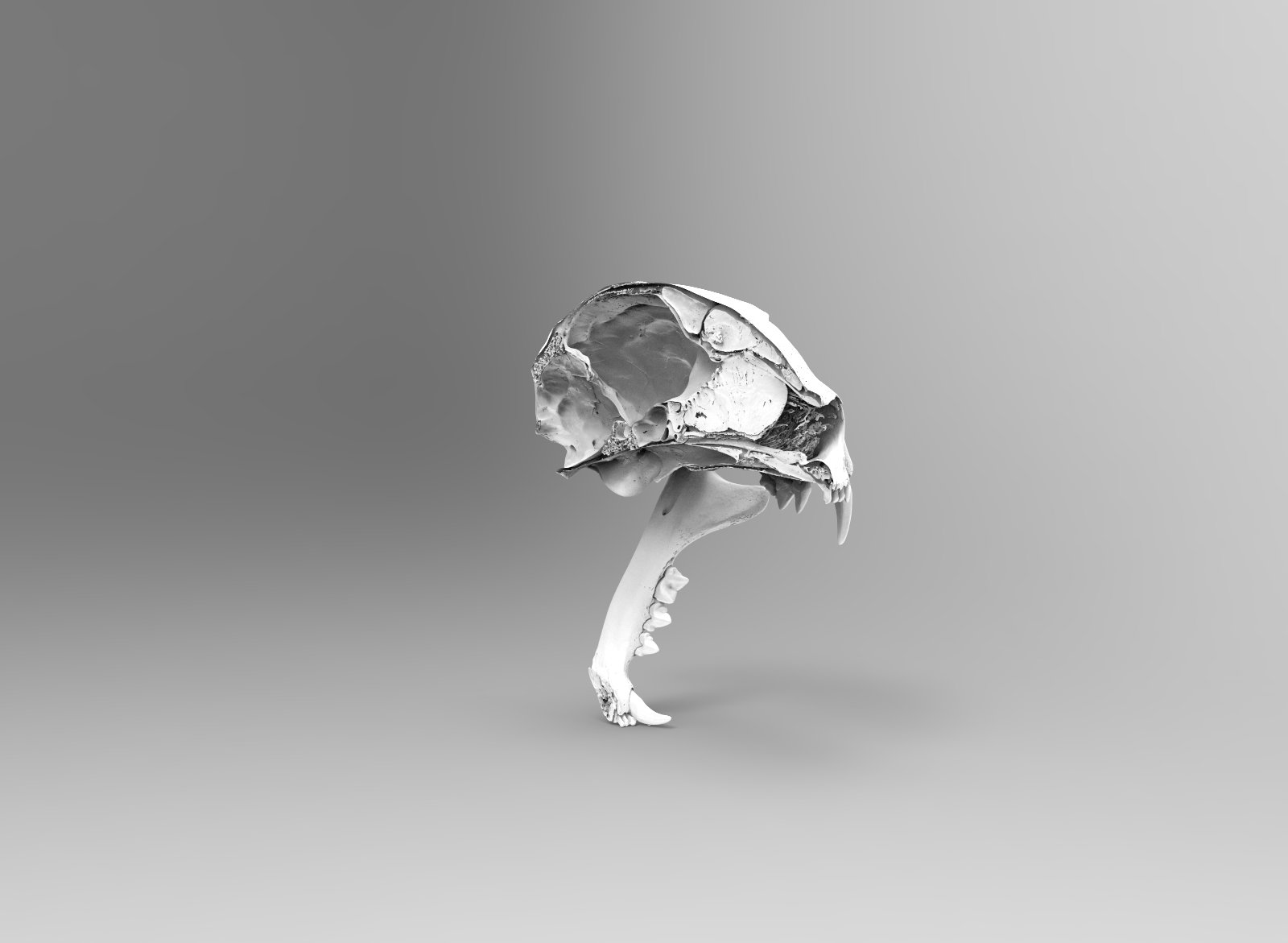

The Nikon Metrology inspection facility supports aerospace, automotive, Formula 1, telecoms, pharmaceutical industries and many more. Samples examined range from the latest hi-tech microchip to a 65million-year-old dinosaur egg. The possibilities are endless.

Results can be supplied as easy-to-interpret reports, with still images, (tiff or jpeg) avi, or complete data sets. Short training sessions are also available enabling customers to operate the X-ray or CT systems independently and carry out their own inspection at the X-ray and CT competence centres.

-

Over 30 years expertise in X-ray CT

Fully equipped laboratories featuring 160-450 kV micro CT systems

In case your in-house CT capacity is limited or not adequate for specific projects, rely on our service capability

Small one-off projects to large batch inspections

Customer-tailored reports and project discussion

Controlled project costs instead of investment in own CT facilities

Short turnaround times

-

Microfocus sources reveal smallest details

Unique high-flux rotating targets for fast scan times

Wide range of systems for scanning small parts to large assemblies

Range of applications from organic to industrial

Non-destructive analysis preserves (expensive) samples

Material analysis, assembly evaluation and metrology CT (compare to CAD, GD&T)

Measure internal and external dimensions simultaneously