Case Study.

Microphone

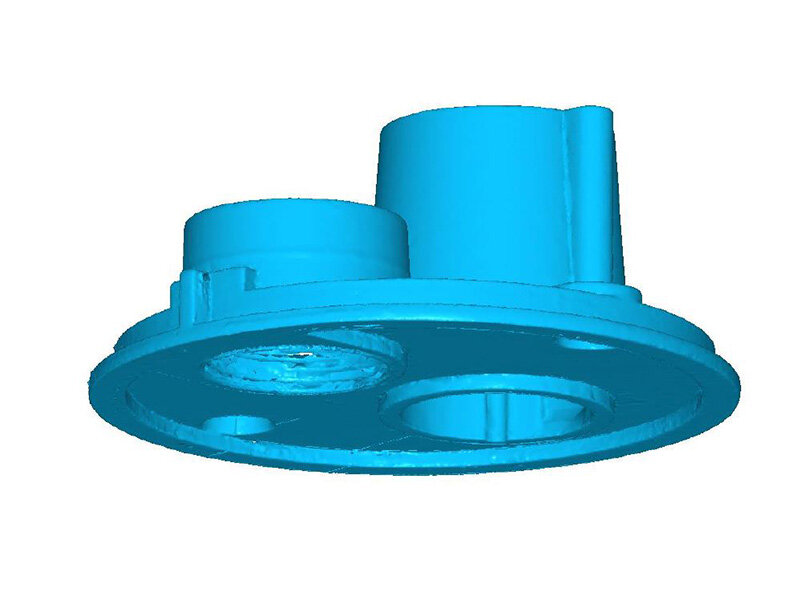

Laser Scanning scanned and reverse engineered one of Aston Microphone’s existing parts which they did not have CAD for.

The Aston Origin is a high-performance cardioid condenser microphone utilising a one inch (1″) gold evaporated capsule. It is versatile enough to use with most instruments and excels on acoustic guitar and vocals.

Laser Scanning has been part of the manufacturing process with PMS Diecasting and GoTools in providing precision measuring and reverse engineering, performance tooling, and quality zinc diecasting services.

Introduction

The Aston Origin is a high-performance cardioid condenser microphone utilising a one inch (1″) gold evaporated capsule. It is versatile enough to use with most instruments and excels on acoustic guitar and vocals.

Laser Scanning

Accuracy: 0.002mm

Equipment: CMM, LC15DX

Purpose: Reverse Engineering & Inspection

Accuracy: 0.002mm

For Aston Microphones, Laser Scanning scanned and reverse engineered one of Aston Microphone’s existing parts which they did not have CAD for. In capturing this 3D form they were able to use its geometry for reference and modification to fit their new design. After three new components within the Origin series were designed and manufactured, customer confidence remained imperative.

To guarantee an insuperable level of customer satisfaction, they laser scanned the three new components for a complete visual inspection accurate to 0.001mm. Knowing that the parts were casted within the agreed tolerances and that there would be no assembly issues, our customer was happy knowing that in turn, their customers would be.

Tooling

Go Tools Ltd created the tooling for PMS Diecasting to diecast the Aston Origin microphone parts.

The tooling was completed and delivered in 8 weeks.

For UK Tooling Services visit www.gotools.co.uk .

The tooling was made from the following hardened steel types, P20 plates (1.27), H13 (1.23), and Gauge Plate (1.28) and capable of creating at least 1 million + castings.

The tooling was created using a 3-axis Mazak for the inserts and die blocks, a 5 axis Hurco for the bolster, an Ops Ingersoll High Speed Eagle V created the electrodes to a 10 micron tolerance and the Ops Ingersoll Gantry Eagle 400 EDM Spark Erosion machine measured at all stages of the process to 10 microns.

Diecasting

Aston Microphones Ltd contacted PMS as they wanted to source a quality British diecaster to work with as they were looking to redesign an existing product previously made in the Far East. Following discussions and a site visit we now diecast the ‘Top Cap’, ‘Mid Cap’ and ‘Bottom Cap’ for the Aston Origin Microphone and its sister product the Aston Spirit Microphone.

PMS design engineers worked together with Laser Scanning and the designers at Aston to reverse engineer the important aspects of the existing product, ensuring that existing components would fit in with the new design that Aston Microphones wanted. This involved mapping critical dimensions on the internal areas of the microphone as well detailing the positions for the standard connectors that are used in the audio industry.

Once the product design was established and finalised, the tooling was designed and delivered within strict time constraints. After the initial sampling and approval process, PMS began volume production of the three die-cast caps in zinc alloy using the 3 impression family tool engineered successfully by www.gotools.co.uk.

To die-cast the parts, one of our Frech DAW80F hot chamber die casting machines, fully automated with ABB robotics was used and the real-time controlled injection system ensured a high-quality component every time. After clipping at the machine one part is tapped, followed by a short vibratory finish and then bead blasting to apply the aesthetic look required by the client. Parts are then shipped for assembly and testing here in the UK.

A successful launch by www.astonmics.com followed by high demand and urgent deadlines has kept PMS busy supplying literally thousands of the required parts. Musicians and artists in recording studios across the globe are now enjoying the sound created by this truly ‘Great’ British audio product! For UK Diecasting Services visit www.pmsdiecasting.co.uk